Used Toshiba Model: DC 800J-MS 800 Metric Ton Horizontal Cold Chamber Aluminum High Pressure Die Casting Machine

Status: Available

We offer for sale, subject to availability, prior sale and the terms listed below:

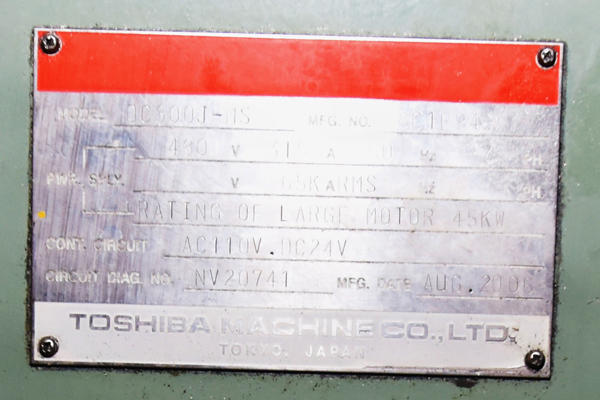

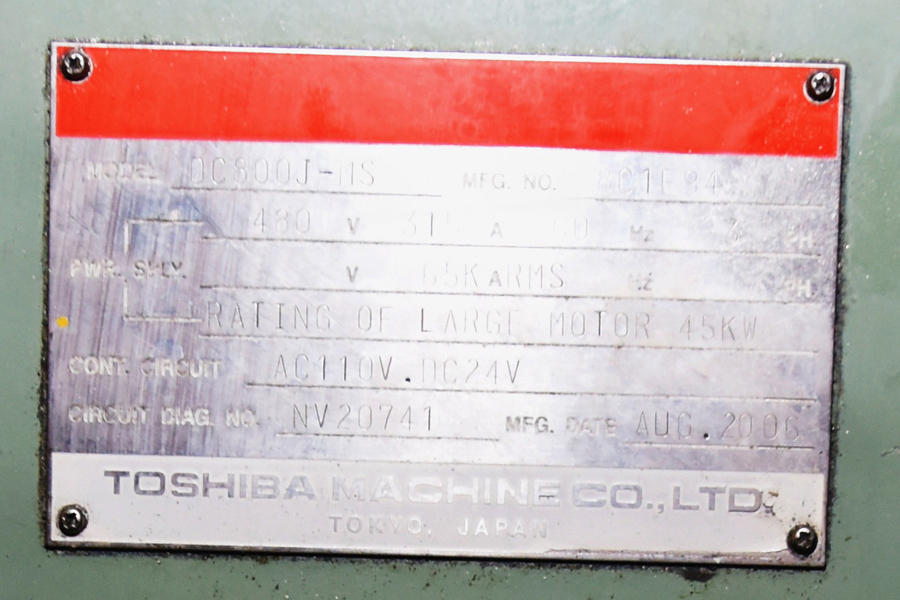

Manufacturer: Toshiba

Model: DC 800J-MS

Size: 800 Metric Ton

Inventory Number: DCM-4163

Used Toshiba Model: DC 800J-MS 800 Metric Ton Horizontal Cold Chamber Aluminum High Pressure Die Casting Machine.

View Available Cold Chamber Die Casting Machines

Features & Accessories:

- Fully automated cell including Die Cast Machine; Toshiba automatic ladle; Toshiba automatic die sprayer, Three (3) Fanuc robots, Toshiba shuttle-bed trim press, robotic deburring cell, quench tank, Sintos Spinner Hanger Shot Blast Machine and much mor

- Toshiba J-MS Multistage Injection System featuring Servo Shot Control with Real-Time Feedback with TOSCAST HMI

- Dual Fully Automatic Tie Bar Pullers on Top Two Tie Bars, Twin Cylinder Hydraulic Bumper Plate Ejection System, Air Safety Ratchet Device

- Factory Equipped with Toshiba DAL Series Automatic Ladle, Toshiba DBS Die Spray Unit

- Downstream Automation including: Fanuc R-2000iB F65 robot for extraction, quench and Trim Press Load; Fanuc M-710iC70 Robot for Trim Press Unload and Part Deburring, second Fanuc M-710iC70 for loading/unloading parts into Spinner Hanger Shot Blast Machine

- Toshiba Shuttle-Bed Four-Post Vertical Trim Press

- Hydraulic Core CircuitsElectric Motorized Die Height

Item Specifications for DCM-4163

| Specifications | |

|---|---|

| Rated Tonnage: |

881 Tons

|

| Platen Dimensions: |

55.12 x 55.12 inches

|

| Space Between Tie Bars: |

36.6 x 36.6 inches

|

| Tie Bar Diameter: |

7.09 inches

|

| Die Stroke: |

29.9 inches

|

| Die Thickness (min. - max.): |

15.75 - 37.4 inches

|

| Injection Force/Intensification Ratio: |

67.24 - 26.46 tons - 1:2.56

|

| Injection Speed, Maximum: |

256 inches per second

|

| Shot Position: |

-9.84 inches

|

| Ejection Stroke/Force: |

4.92 inches - 41.58 tons

|

| Motor Size: |

60.3 HP

|

| Machine Weight: |

43 tons

|

Document(s) For This Machine

Description

Used, Toshiba Model DC 800J-MS 800 Metric Ton Horizontal Cold Chamber Aluminum High Pressure Die Casting Machine For_Sale, Features Include: Toshiba J-MS Multistage Injection System featuring Servo Shot Control with Real-Time Feedback with TOSCAST HMI, Dual Fully Automatic Tie Bar Pullers on Top Two Tie Bars, Twin Cylinder Hydraulic Bumper Plate Ejection System, Air Safety Ratchet Device, Factory Equipped with Toshiba DAL Series Automatic Ladle, Toshiba DBS Die Spray Unit, Downstream Automation including: Fanuc R-2000iB F65 robot for extraction, quench and Trim Press Load; Fanuc M-710iC70 Robot for Trim Press Unload and Part Deburring, second Fanuc M-710iC70 for loading/unloading parts into Spinner Hanger Shot Blast Machine, Toshiba Shuttle-Bed Four-Post Vertical Trim Press, Hydraulic Core CircuitsElectric Motorized Die Height, Toshiba controls, second Hand, DCM-4163

PURCHASER'S (Buyer's) RESPONSIBILITY AND INDEMNITY: Used machines, equipment or any part thereof, may not incorporate approved activating mechanisms, operator safety devices or safety guards as required by OSHA or otherwise. It shall be a Purchaser's (Buyer's) responsibility to ensure that any and all merchandise or equipment purchased from Die Cast Machinery, LLC or its affiliates is installed and operated in a proper and safe manner. Purchaser (Buyer) also acknowledges that it may have to install or change guards, safeties, warnings or other components to ensure that the merchandise or machines purchased will conform to all laws, codes, regulations, ordinances, statutes, insurance requirements and industry standards. Purchaser agrees to defend, indemnify and hold harmless Die Cast Machinery, LLC from and against all suits, claims, costs, damages and expenses, including, but not limited to, reasonable attorneys' fees, arising out of, or in connection with, the transportation, purchase, ownership, or use of the merchandise or equipment sold hereunder. Information has been obtained from sources deemed reliable, buyers should avail themselves of the opportunity to inspect the items before purchase.